Posted on: 1st November 2023 by Dr. Ceri Williams

At Innoval we support the extrusion industry in many different areas, from process audits to alloy development. In this article, by looking at billet homogenization, we highlight how techniques pioneered in our laboratories can help solve process issues on the ground.

A standard extrusion practice for 6XXX aluminium alloys involves 5 main stages:

If the mechanical properties of the extrusions aren’t as expected, the focus will usually be on the initial composition of the billet or the extrusion/ageing conditions. Very rarely does anyone question whether the homogenization could be at fault. In reality, the homogenization stage is essential to producing high quality extrusions. If you don’t control the homogenisation step it can lead to:

- Increased breakthrough pressure.

- More defects.

- Streaked texture after anodizing.

- Lower extrusion speeds.

- Poor mechanical properties.

The homogenization stage has two main purposes. Firstly, to refine the iron-bearing intermetallics and, secondly, to redistribute the magnesium and silicon. By looking at the microstructure of the billet before and after homogenization, it is possible to predict whether or not the billet will perform well during extrusion.

The effect of billet homogenization on hardening phases.

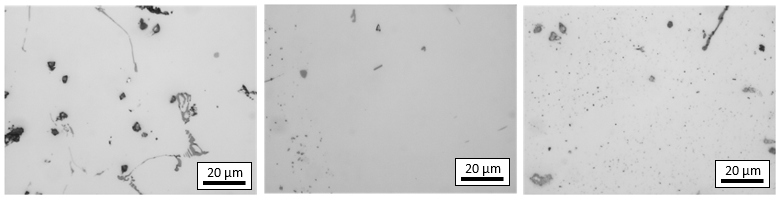

In 6XXX extrusions, the strength comes from the Magnesium (Mg) and Silicon (Si) rich phases that form during ageing. The ability to form these phases relies on having the elements in solid solution before the ageing process starts. For the Mg and Si to end up in solid solution, you must cool the metal quickly from above 530°C. Above this temperature, Mg and Si naturally dissolve into the aluminium. However, during the extrusion process there is only a short period of time when the metal is above this temperature. To ensure that all the Mg and Si dissolves during this time, the Mg and Si particles need to be relatively small. Unfortunately, during casting, the Mg and Si precipitate out as relatively large chunks of Mg2Si as illustrated in Figure 1a.

A typical homogenization cycle for 6060 billet would be 560°C for 2hrs. During this process, because the billet is above 530°C for an extended period of time, the Mg2Si dissolves. When the billet cools down it precipitates back out in a much finer distribution as you can see in Figure 1c. If the homogenization temperature isn’t high enough, or the time isn’t long enough, some large particles of Mg2Si will remain. When this happens, less Mg and Si are in solid solution after extrusion. Consequently, it is not possible to form as high a density of hardening precipitates, and this results in lower mechanical properties.

The effect of billet homogenization iron-containing intermetallics.

The iron (Fe) containing phases have more of an impact on fracture toughness than strength. In 6XXX alloys, during casting, the iron-containing phases tend to form as β (Al5(FeMn)Si or Al₈.₉(FeMn)₂Si₂). These phases are large with sharp corners and angular features that interfere with the extrusion process (highlighted in Figure 2a). During homogenization, the heavy elements (Fe/Mn etc) can diffuse, and the large angular phases transform to become smaller and more rounded (Figure 2(b)).

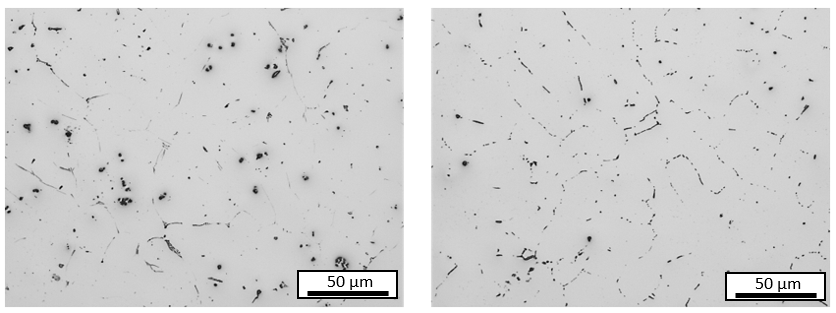

From the optical images, it is difficult to distinguish the various phases. Furthermore, it is impossible to reliably quantify the different phases in the microstructure. At Innoval, we can quantify how well homogenized a billet is by using our in-house feature detection and classification methodology. This technique can give us a figure for the %α in the billet. We are then able to quantify how good the homogenization is.

Feature Detection and Clarification (FDC) method.

Figure 3a shows a polished sample that we analysed using a scanning electron microscope (SEM). We then employed greyscale thresholding to isolate and identify the intermetallic phases. They appear white in the SEM image in Figure 3b. This technique allows us to analyse areas up to 1mm2, which means that we can collect data from 1000+ individual features in one go.

Composition of the particles.

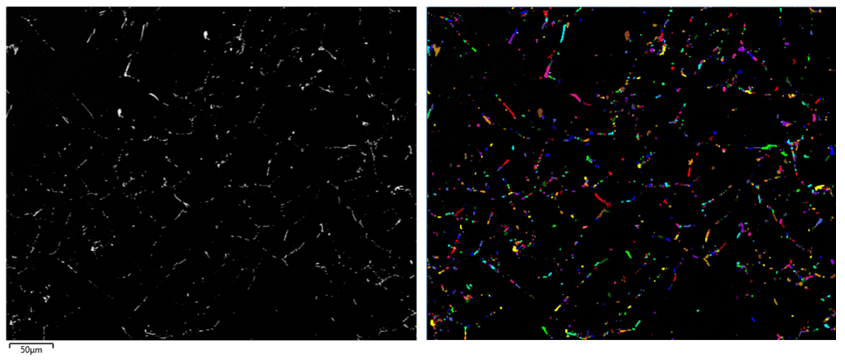

The Innoval system has an Oxford Instruments Xplore 30 Energy-dispersive X-ray (EDX) detector. This allows rapid collection of EDX spectra from each of the identified points automatically. From these spectra we can get an indication of the composition of the particles. Then we can infer a relative value for the ratio of Fe:Si.

Depending on how much Manganese (Mn) or Chromium (Cr) there is in the alloy, we can also include other heavy elements such as these. This means that in the case of some 6XXX alloys (which sometimes contain appreciable levels of Mn) we are able to refer to the (Fe+Mn):Si ratio as standard. We can then compare these ratios to the (Fe+Mn):Si ratios for the known iron containing intermetallic phases.

The β phase (Al5(FeMn)Si or Al₈.₉(FeMn)₂Si₂) has an (Fe+Mn):Si ratio of 2. The α phase (Al12(FeMn)3Si or Al₈.₃(FeMn)₂Si) ranges from 4-6 depending on the exact composition. Our custom software allows us to set a cut-off point and categorize each particle as either α or β, and then see where in the microstructure each of those particles are, as shown in Figure 4. This gives us an approximation for the % transformed α in a homogenized billet.

What the data can tell us.

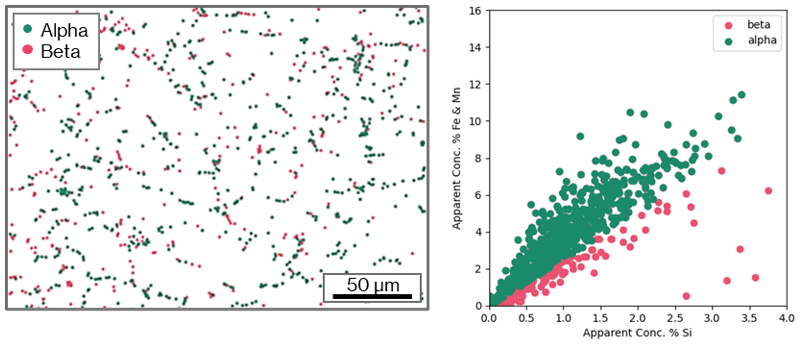

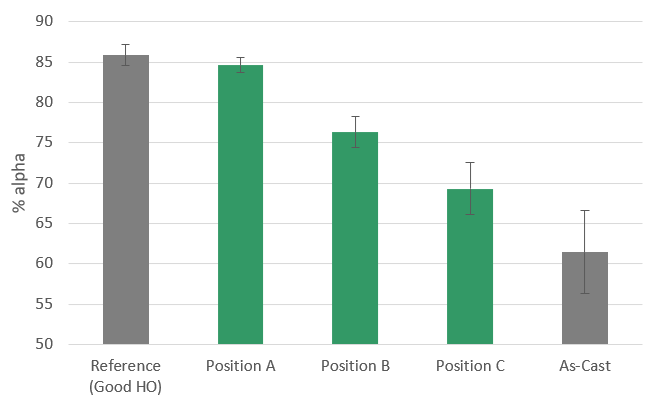

Figure 5 shows an example of how we use this information. In this case we can use the results to establish that a particular furnace is not heating uniformly. It’s also likely that it is not reaching the set-point temperature. For this case, and others like it, it’s essential to have both the as-cast material and a section of known good material for reference. Without these, we would not know the upper and lower limits of the expected levels of % α for that particular composition of billet.

How we can help you.

If your company is experiencing any issues regarding billet quality, please don’t hesitate to contact us. It may be that you source your billets from more than one supplier, and you’re finding that the quality from one is noticeably less than from the others. We can find the underlying cause of what’s going on by conducting what we call ‘supplier fingerprinting’.

In addition to the techniques described in this article, we offer a range of support to extrusion companies. This includes extrusion process auditing and optimisation (at the press, heat treatment and in packing), as well as training and product development. Our experts currently work with some of the world’s largest extrusion companies.