Posted on: 7th June 2019 by Private: Chris Pargeter

Like all the process variables in a rolling operation, it’s important to monitor and control the rolling lubricants. In this blog I’ll introduce some of the common monitoring methods.

Cold and foil rolling operations

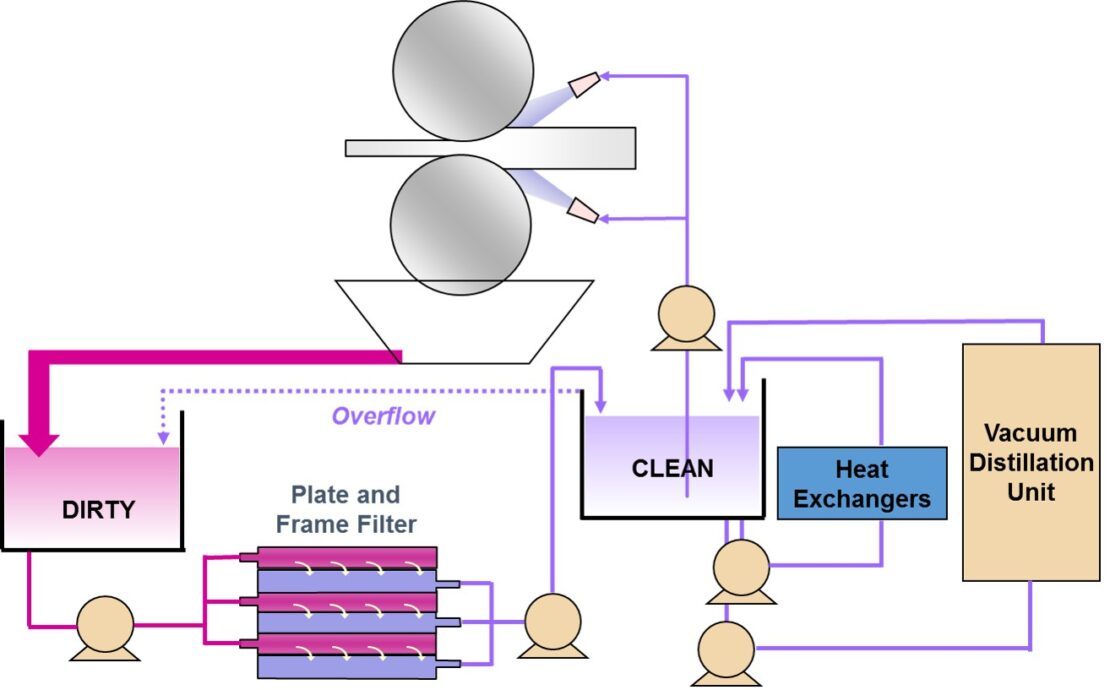

These operations predominantly use oil-based rolling lubricants (Figure 1). However, some mill systems can accommodate water-based alternatives. Traditional formulations comprise a base oil, load bearing additives, anti-oxidants and possibly wetting/antifoaming agents. The base oil dissolves the additives and provides sufficient viscosity to maintain stable mill rolling conditions. The additives deliver load bearing capacity and frictional control.

The formulated lubricant should evaporate cleanly during annealing in either air or inert gas atmospheres.

Rolling lubricants in use

During use, rolling lubricants can become modified and contaminated in several ways. These are as follows:

- Evaporation causes the loss of volatile components, increasing flash point, viscosity and initial boiling point.

- Frictional wear introduces metallic debris into the lubricant.

- Additives react chemically with the roll and product surfaces to form soaps.

- Exposure to high temperature and pressure, combined with air, increases the potential for oxidative degradation.

- Ingress of other mill lubricants and/or water contaminate the rolling fluid, causing viscosity changes, variable friction and promote surface staining.

It is important to monitor and control these changes to maintain lubricant performance.

Monitoring Techniques

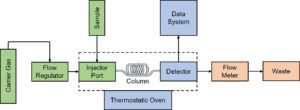

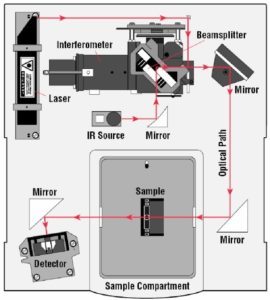

Load bearing additive analysis commonly uses Gas Chromatography (GC, Figure 2) and Fourier Transform Infrared (FTIR, Figure 3) techniques. These techniques can also determine anti-oxidants such as BHT (2,6-Di-tert-butyl-4-methylphenol). GC separates components based on both polarity and volatility, so can distinguish and quantify mixtures. FTIR identifies and quantifies constituents through characteristic functional groups in molecules.

Aluminium soaps generated during rolling are difficult to characterise using FTIR due to their variable composition. Furthermore, GC analysis generally requires a pre-column sample derivatisation for accurate quantification.

It is more usual to measure aluminium soap indirectly through its ash content (ASTM D482-13). This involves the thermal decomposition of any organic material to leave a metallic oxide-based residue, which can then be weighed. Testing pre-filtered lubricant determines the soluble ash level. Total ash is obtained without pre-filtering.

Contamination of rolling lubricants

Rolling oil contamination by mill fluids is inevitable and can cause surface staining during annealing. One distinguishing feature of these contaminants is their different viscosity compared to the rolling oil itself. Therefore, regular monitoring of this property using a kinematic viscometer is a quick way to ascertain if there is contamination.

Mill oil contaminants can reduce lubricant volatility and increase its staining tendency. It is also possible to monitor this by way of its ‘gum residue’ or ‘heavy-end’ content. Two of the commonest techniques for these measurements are:

- A standard test method for existent gum by jet evaporation (ASTM D381).

- By a distillation technique first developed by the Allegheny Company (US).

The gum residue test (Figure 4) was developed originally for aviation fuels. It was subsequently adopted for cold and foil rolling lubricants to help predict staining propensity on sheet and foil.

The ‘Allegheny Distillation’ differs from conventional distillations in recording the temperature of the oil rather than the vapour. It utilises an inert (N2) atmosphere which makes it possible to recover the ‘heavy ends’ without thermal cracking. This makes the test more relevant to the annealing operation.

Water control

Finally, the control of water to very low levels in oil-based rolling lubricants is important to avoid problems of friction and surface quality. Water can compromise cooling, shape control and filtration. Furthermore, it increases surface staining potential. The usual method for water analysis is coulometric Karl Fischer titration (ASTM D6304). This technique has benefited greatly from the development of automated titration systems and improved reagents that give superior end-point detection.

Help when you need it

Within Innoval we have a lot of knowledge and experience in the lubrication of aluminium surfaces through hot and cold rolling, and through fabrication processes such as can making and automotive pressed panel production.

If you have a process problem linked to your lubricant, we can help you solve it. Our decades of experience of working with lubricants mean that we’ve probably seen your problem before and so will be able to solve it quickly. If you have any questions, please contact us.

Finally, our Aluminium Rolling technology Course includes a module on rolling lubrication. You can read more about the course here and download a registration form (which contains the agenda) for the next course.

Images courtesy of *ThermoFisher and **Stanhope-seta