Posted on: 13th April 2017 by Vicente Martin

In an earlier blog post I discussed how to determine the roll ground shape in order to make the best use of the flatness actuators in an aluminium rolling mill. In this post I will briefly discuss the advantages of improving your roll grinding operation.

Rolls for rolling mills

Rolling mills today are extremely complex machines with advanced automation control. The key tools that actually deform the metal, the rolls, are in many operations just an auxiliary tool. As such, grinding shops can become a second tier auxiliary operation that appears to bring no value to the business.

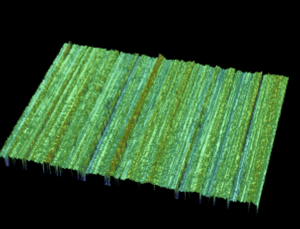

Grinding a roll is a very delicate operation. It not only influences the shape and geometry of the rolled material, but will produce a certain topography on the rolls. This will be a key element in defining the surface appearance of the final product. Furthermore, it will have a definite influence on the friction in the roll gap and the rolling speed.

Roll grinding and foil rolling speed

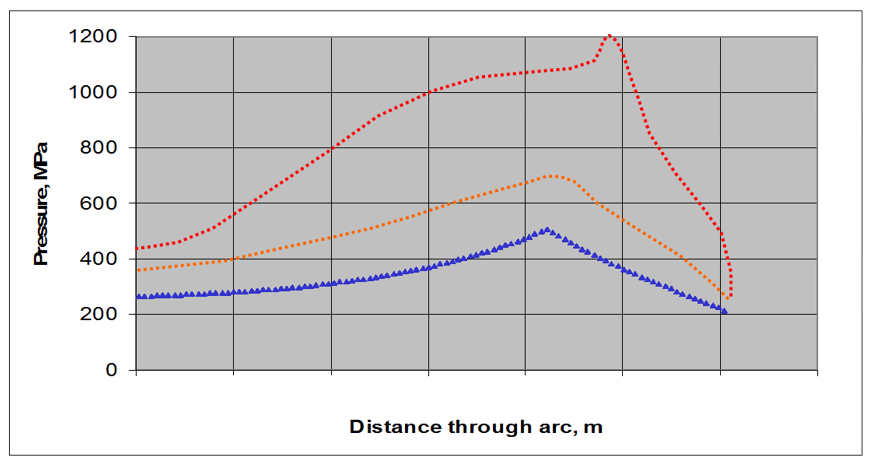

Foil rolling is extraordinarily dependent on the friction in the roll gap. This is because the arc of contact can be more than ten times the size of that exhibited in cold strip rolling. As a result, a friction hill dominates the deformation process.

The impact of this is the largest of any rolling process. In fact, roll grinding directly influences the speed of the rolling mill. Due to this, over the years foil rollers have developed grinding strategies capable of maximising rolling speed whilst keeping the desired surface appearance and enhanced surface uniformity.

Wear of the rolls makes the speed change through the process. However, there are techniques to minimise this change and also to maintain rolling speed through a campaign. At Innoval we’re able to offer help with both of these.

Roll grinding training

We can help you maximise your potential productivity by providing critical knowledge to the personnel taking care and using the rolls.

In fact, one of our most popular courses focuses on the grinding operation. It takes the audience through a two day exhaustive review of grinding technology.

What’s more, we’re able to examine and suggest improvements to your surfaces or grinding practices. As one of our clients said recently; “after your visit we increased the speed of our mills by 20-30%”.

Another one of our clients, MEYER, operates rolling mills in both Hong Kong and Thailand. Their Technical Manager wanted to increase quality through improving their in-house roll grinding facility. You can read the case study here.

Finally, if you’d like to know more about our grinding courses or anything else I’ve mentioned here, please get in touch.