Posted on: 3rd June 2016 by Prof. Geoff Scamans

Everyone on the planet consumes an average of 44 kg of our natural resources every day. The rate of this consumption per person is much higher in the developed world, for example North America is at 88 kg/day whilst Africa is at 11kg/day. The rate of resource consumption in the developing world is still at the level of the first farming communities.

The industrial revolution that started in the heart of the UK was the catalyst for the rapid rise in resource consumption, and more of our natural resources have been consumed since its inception that in all previous human history.

The consequences of this dramatic rise in resource consumption are becoming more and more obvious. The most alarming estimates of its consequences are that by 2050 the world’s population will have risen to 9 billion people and our resource consumption will have doubled. At this time we will need the resources of about six planets the size of Earth to maintain planet sustainability.

The energy benefits of recycled metals

The different ages of civilisation have been classically categorised by the dominant materials of each time from the Stone Age to the Bronze Age and the Iron Age. The Stone Age was a broad prehistoric period that lasted between three and four million years and was superseded by the Bronze Age from about 3000 BC, and then the Iron Age from 800 BC. The Iron Age became The Steel Age that persists today.

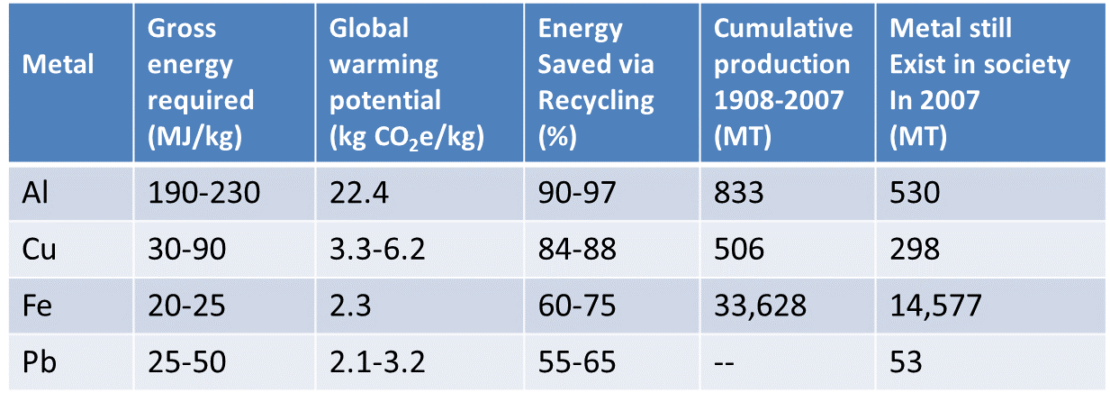

In reality the present world industry depends on more than just steel, and the four major industrial metals are iron, copper, aluminium and lead. The table below shows the amounts of these metals that have been produced to date and how much remains in stock:

All of these metals require significant energy in their primary production from ore and they all make a significant contribution to global warming. However, they are all much less energy intensive when they are recycled. It is quite obvious that we should focus on their recovery and re-use from the exiting stock rather than the production of further primary metal.

This is not a new concept and was expressed most eloquently by the Noble laureate Glenn Seaborg in 1978 who stated that “the present materials situation is literally reversed; all waste and scrap, what are now called secondary metals, become our major resources, and our natural, untapped resources become our back-up supplies”. This was in an excellent article “Aluminum, the Magic Metal” in the National Geographic Magazine.

Glenn Theodore Seaborg was an American chemist whose involvement in the synthesis, discovery and investigation of ten transuranium elements earned him a share of the 1951 Nobel Prize in Chemistry. Element 106 was named “seaborgium” in his honour whilst he was still living.

Recycled aluminium

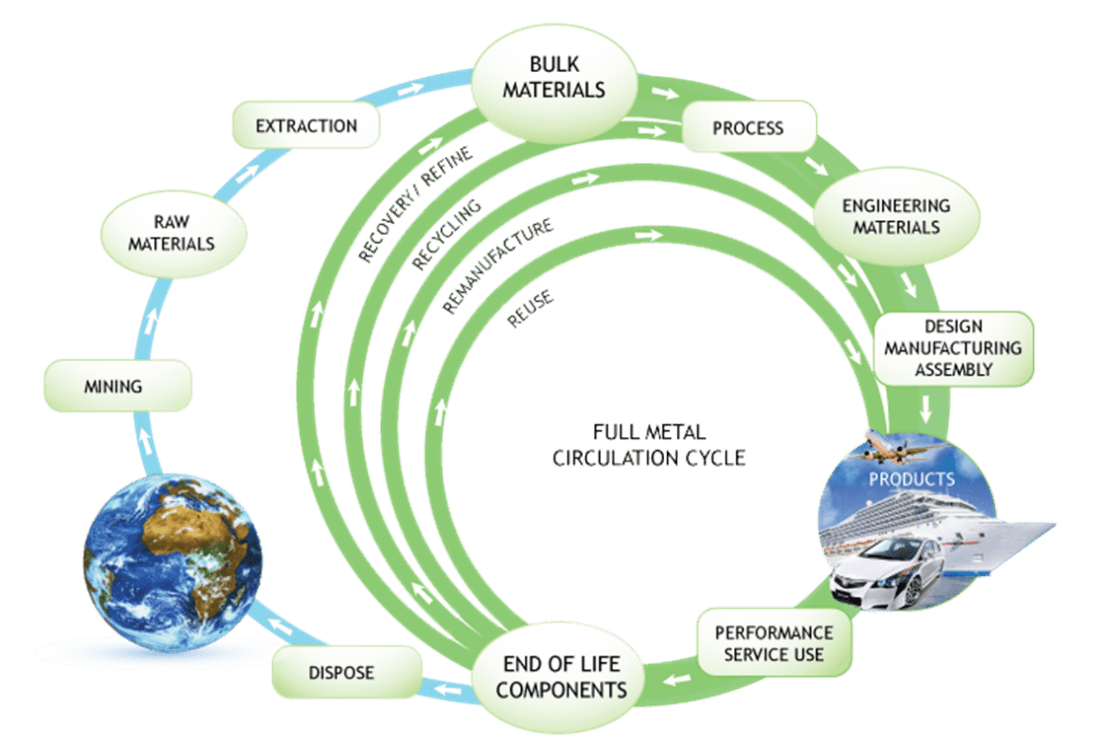

The recovery and reuse of secondary metals, particularly aluminium, has been the vision of the Brunel Centre for Advanced Solidification Technology (BCAST) at Brunel University for more than a decade under the leadership of Professor Zhongyun Fan. One of his students has put the concept into the simple diagram shown below:

The first requirement is to use the minimum amount of metal for the intended design and to design for its recovery and re-use. The recovery processes get progressively more complicated from simple re-use to remanufacture to recycling and then to recovery and refining.

From the aluminium perspective the embedded carbon content in recycled aluminium is very similar to that of recycled steel but, as the density of aluminium is lower, the embedded carbon content in a manufactured component for recycled aluminium is lower than that of the same component made from recycled steel. This means that recycled end-of-life aluminium is unbeatable as the lowest carbon burden material for use in engineering applications.

The most important applications are all transport related particularly future car manufacture. Recycled aluminium is the best material choice for the cars of the future provided it is recovered in usable form from end of life vehicles. This is the major challenge for the industry particularly where primary aluminium is not available to provide the low carbon vehicles of the future and to fully establish the Aluminium Age.

Innoval has been involved in many cutting-edge projects to increase the use of recycled aluminium. One such project is REALCAR which you can read more about here.