Posted on: 8th November 2016 by Kyle Smith

All machines vibrate during operation. However, only a few of these vibrations cause problems to the product or the machine itself. Typically, the most damaging vibrations involve a natural resonance of the machine which significantly increases the motion of critical components. Rolling mill vibration is no different.

The most damaging modes of mill vibration involve some very specific natural resonances of the mill stand. If no structural resonances are excited then the vibration amplitude is simply a consequence of the way the mill responds to a cyclic exciting force acting at a particular location within the mill.

Torsional chatter

The simplest type of mill vibration is found in all mills. It is a forced vibration due to roll eccentricity and so occurs at roll rotation frequencies. These frequencies are usually lower than any of the resonant frequencies of the mill stand. Therefore, gauge variation is a result of the stiffness response of the mill and the material on the mill. In some cases, at higher speeds, it is possible to worsen this vibration by excitation of torsional resonances of the main, unwind or rewind drives. These torsional resonances usually occur at frequencies up to around 30Hz. Furthermore, if the mode involves a fluctuation of work roll speed then there may also be interaction with lubricant instabilities in the roll bite. This phenomenon is sometimes referred to as torsional chatter.

Problematic mill vibration

Natural resonances of the rolling mill involve translational motion of the rolls. This typically occurs at frequencies greater than 50Hz. Of the large number of these resonant modes that could become excited during rolling, only a few will cause damage to the metal in the mill or the surfaces of the rolls. Excitation of these specific, damaging modes are the typical cause of the phenomena of third octave gauge chatter and fifth octave roll and strip chatter marking. Because of its self-exciting nature, third octave gauge chatter still poses a difficult problem for the industry. In some instances it causes significant financial loss due to a reduction in cold rolling speeds. Fifth octave chatter is more prevalent on mills and can cause significant surface quality issues.

I will focus on these two key mill vibration phenomena in this post and the next one.

Third Octave Gauge Chatter

A third octave gauge chatter problem can produce significant gauge variation. It can vary from a few percent of nominal gauge up to higher percentages and can even cause strip breaks. This is due to excitation of one of the natural resonances of the mill stand. Commonly these natural resonances have frequencies between 100 and 150Hz, but sometimes as high as 300Hz. These frequencies are much higher than the bandwidth of most gauge control systems. Consequently, the gauge variation is an average over several vibration cycles and so is not seen by the system.

The onset of gauge chatter vibration occurs at high rolling speed. Usually you can only stop it by reducing the speed of the mill. It is rarely possible to stop the vibration by increasing speed if the mill is truly unstable. Typically the amplitude of vibration will rise very rapidly (in less than a second). At this vibration frequency it will be audible. Without vibration monitoring equipment, this audible noise is often the only indication to the mill operator that the mill is vibrating. He/she may also feel some lower frequency modes in the ground supporting the mill housing.

Uniform gauge variation

During gauge chatter the gauge variation will be fairly uniform and in-phase across the strip width. Careful off-line thickness measurement of the final product is often the only way to detect it.

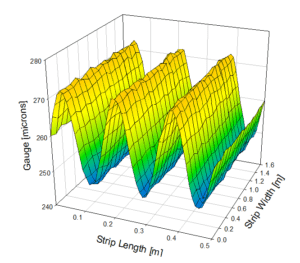

Figure 1 shows a simulated gauge variation produced by vibration with several vibration cycles per metre length of strip.

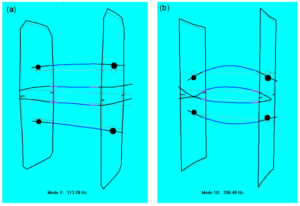

The images in Figure 2 show the typical rolling mill resonances that can become excited to produce gauge chatter.

The most common mode for a 4-high mill is shown in Figure 2 (a) and involves the top two rolls moving vertically in anti-phase against the bottom two rolls. The mill stand housing is also involved in the vibration mode. There is very little deflection of the work roll barrels. This explains why the gauge variation is similar at all positions across the strip width.

Self-excited mill vibration

There is a special class of vibration called self-excited vibration. Self-excited systems begin to vibrate of their own accord spontaneously. The amplitude increases until some non-linear effect limits any further increase. The motion itself creates the alternating force that sustains the motion. It stops when the motion stops. Self-exciting behaviour often involves a natural resonance which provides structural flexibility. Common examples include machine tool chatter and the sounds from some musical instruments. Other examples include aeroplane wing tip flutter, chimney sway and bridge vibration. A good example of a self-excited bridge vibration is the famous Tacoma Narrows bridge that collapsed in 1940 due to high wind speed.

Feedback mechanism

Third octave gauge chatter also falls into the category of self-excited vibration. Like the Tacoma Narrows bridge, the cold mill will vibrate without an independent external cyclic force to excite it. This means that, during gauge chatter, there is a feedback mechanism that provides a sustaining force to increase the mill vibration amplitude which is a consequence of the vibration motion itself. This mechanism has its origins in the roll bite. It is a consequence of the continuity of mass flow through the stand.

The feedback mechanism is purely mechanical. The gain of this self-exciting feedback loop is dominated by the speed of the strip in the mill. So, just like increasing wind speed made the bridge unstable and fed energy into the oscillation, increasing strip speed will make the mill unstable and will feed energy into this type of mill vibration.

Threshold speed for vibration

This explains why rolling mills prone to gauge chatter vibration exhibit the problem suddenly as the speed is increased above a threshold value. Normally you cannot exceed this threshold speed. To do so would cause strip break and/or damage to the mill.

Other factors such as the material being rolled, the rolling conditions and the natural damping of the mill stand resonance will all affect the threshold rolling speed for vibration. However, these are difficult to change and none vary as significantly as the mill speed during a particular rolling pass.

Third octave gauge chatter is seen in single stand cold mills and cold tandem mills. However, the latter is a little more complex due to interaction between the stands via the interstand strip.

The rolling speeds on cold mills suffering from this type of gauge chatter vibration are often constrained for certain products. For these products the rolling speeds are kept below the threshold speed at which mill vibration occurs. Sometimes this is with the use of on-line vibration monitoring equipment. Consequently, there can be a significant loss of productivity if the mill is a bottleneck machine.

Solving mill vibration problems

There are various ways to solve this problem and increase the threshold rolling speed of cold mills. Thankfully, we have a lot of experience in this area. One of the tools we use to do this is the Innoval Mill Vibration Model which is a finite element-based model.

This vital tool assists in the solution of rolling mill vibration problems faced by the entire metal rolling industry. The model uses available mill data to predict all the key natural resonant modes of vibration of any rolling mill. Please contact us if you’d like to know more.

In my next post I will talk about Fifth Octave Chatter which manifests itself as roll and strip chatter marks.

This blog post was originally written by Dr Tom Farley who has now left the company. Please contact Kyle Smith if you have any questions.