Posted on: 5th October 2021 by Rachel Wiffen

Life Cycle Assessment and Sustainability Analysis are becoming ever more important. This is because the environmental impact of products and services is increasingly in the public’s consciousness, as well as the political arena. Furthermore, this focus on sustainability is coming from investors as well as consumers. It is, therefore, vitally important to understand the environmental impact of your product or service. That’s where Life Cycle Assessment comes in and, in this blog, I will briefly explain what it is.

What is Life Cycle Assessment?

Life Cycle Assessment (LCA) is a methodology to assess the environmental impact of a product or service by the compilation and evaluation of inputs, processes and outputs of a product system. The product system can include the making of the primary materials and further processing of the product. It can also include transport, waste streams, the use phase, end of life (EoL) etc. Boundaries detailing what will be in and out of scope define the product system.

LCA can study an entire process from beginning to end which we refer to as ‘Cradle to Grave’. It can look at the making of the product, which we call ‘Cradle to Gate’. Finally, it can consider a particular process in isolation, which we call a ‘Gate to Gate’ study.

LCA uses structured and standardised methods such as ISO 14040 and ISO 14044. However, despite this, you should only compare products and processes examined within the same study because there are many intricacies within LCA. Furthermore, an external reviewer would need to assess a comparative study to ensure the report and comparison are non-biased.

The LCA process typically has four stages. These are Goal and Scope definition, Life Cycle Inventory Analysis (LCI), Life Cycle Impact Assessment (LCIA) and Life Cycle Interpretation and Reporting.

LCA’s are iterative in nature. As issues and opportunities arise, the methodology and associated documentation are adapted accordingly to meet the goal of the study.

The importance of good quality data

Like most studies, the validity of the final result depends on the quality of the inputs. Therefore, when conducting an LCA, it’s important to make sure you capture all the relevant processes.

For a product which incorporates aluminium, this is where Innoval excels. Our specialist aluminium industry knowledge, combined with the latest Life Cycle Assessment software (GaBi), means we’re perfectly placed to offer reliable and independent Life Cycle Assessments to the aluminium industry.

Applications of Life Cycle Assessment

There are many applications for Life Cycle Assessment studies. They include product development, identifying opportunities to improve environmental performance, strategic planning, and decision-making. Furthermore, there are marketing reasons such as for an ecolabelling scheme or to make an environmental claim.

Now I’ll briefly describe the four stages of a Life Cycle Assessment.

Stage 1: Goal and Scope Definition

Before starting an LCA you must define the goal with the commissioner of the study. The goal definition can be quite short and to the point. It defines the purpose of the study and identifies the target audience.

An example goal definition might be; ‘to conduct an LCA analysing the environmental impact of a single-use bottle of X material and X fill volume’. If you were completing a comparative study the goal might be ‘to conduct an LCA analysing the environmental impact of a single-use bottle, made from PET and X fill volume compared to alternative beverage containers (aluminium cans, glass bottles, beverage cartons).’

The Scope definition tells you what you’re going to analyse and how you’re going to do it. It describes the details and depth of the study. This is where you define what will be in or out of scope, and the functional unit (FU) that you’ll assess. The FU is a quantified description of the function of the product which will serve as the reference for the study. Following the previous bottle example, the FU could be, ‘a single-use bottle made of X material with X fill volume’. Similarly, for the comparative study the FU might be ‘X units of beverage packing of X fill volume’.

Stage 1: System Boundaries

In Stage 1 you define the system boundaries – what will be in and out of scope. For the bottle example, you might choose to analyse the manufacturing of the bottle up to where it leaves the factory or where is reaches the customer to include transportation. You might scope-out the use phase of the bottle, and so would not include this within the system boundary. You might also consider the filling process and manufacture of the liquid to be out of scope.

In this stage you also identify whether you will be able to use primary data (from foreground systems – data you can measure yourself) or other data sources (background systems – data that has been collected and verified by third parties). Background systems include industry data from a report, or data that is collected by Sphera and is available in the Gabi Software.

Stage 2: Life Cycle Inventory Analysis

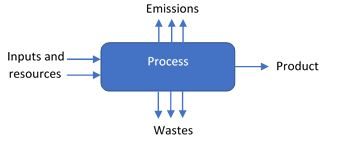

The Life Cycle Inventory starts with a model of all the flows into and out of the product system. You then collect data for those modelled activities that are within your system boundary. The simple example in Figure 4 shows the flows in and out of one process.

Data quality is important. There are lots of data considerations, such as checking that your data will be relevant and representative over time, technologically and geographically.

It’s important to assess data sources for reliability and accuracy, and to identify any gaps or uncertainties. Innoval’s experience in the aluminium industry over the last 18 years means we have access to good quality and accurate data for LCA studies.

Stage 3: Life Cycle Impact Assessment

Life Cycle Impact Assessment is the calculation stage. An impact assessment methodology uses the data you’ve collected to calculate the results of the study. Impact assessment methodologies such as; CML2001-Aug2016, PEF CFF or ReCiPe, aim to turn the results from the Life Cycle Inventory Stage into corresponding scores for environmental impact categories.

The methodology you choose depends upon the type of product or service you’re analysing, the geographical location, and whether you need to align with other LCA studies. For example, if a company has a particular methodology preference, they may like all their LCA reports to be in that format.

The calculated environmental impact categories, such as global warming potential (GWP) and primary energy demand (PED), take into account all contributing outputs. For example, GWP is calculated in kg CO2 equivalent. This includes Carbon Dioxide (CO2), Methane (CH4), Nitrous Oxide (N2O) and other gases. These gases are multiplied to give a relative effect compared to the GWP of CO2.

If we look at Methane and Nitrous Oxide, both have a higher impact on GWP than Carbon Dioxide. Consequently, where CO2 would equal 1, to get the relative effect, CH4 is multiplied by 25 and N2O by 265. [IPCC, 2014: Climate Change 2014: Synthesis Report.]

Stage 4: Life Cycle Interpretation and Reporting

The last stage is the Life Cycle Interpretation and Reporting stage. This is where you draw conclusions and make recommendations. The final report should follow the intentions defined in the scope.

LCA for the aluminium industry

Over the last 18 years, Innoval’s industry-leading knowledge and strong history of collaboration have enabled us to partner with global producers to deliver innovation.

Sustainable aluminium technologies are starting to make an impact, and we are involved in many collaborative R&D programmes which have a sustainability focus. Innovation will be key for positioning aluminium as the material of choice in the circular economy. Consequently, Life Cycle Assessment and Sustainability Analysis will be essential for validating this.

We would welcome the opportunity to work in partnership with you to support and accelerate your strategic, sustainable and/or LCA goals. Please contact us for further information.