Posted on: 17th February 2017 by Dr. Gary Mahon

Many companies are interested in establishing if single stand hot reversing mills are capable of producing Can Body Stock (CBS). This is for potential supply to either can-making plants in that country or, if the product can reach world-class standards, for export. Significantly more expensive multi-stand tandem rolling mills currently produce almost all CBS. This is because these mills are capable of producing the required earing characteristics in the final product.

What is earing?

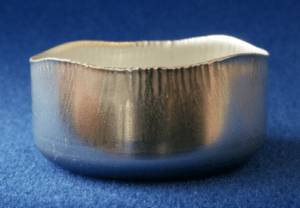

Earing is the non-uniform height of a can sidewall. It appears after any deep drawing operation, such as that used in beverage can manufacture.

Figure 1 shows a very simple example of severe earing after a laboratory drawing test. This is something we can do in our material testing labs at Innoval.

Earing from a multi-stand mill

The good earing that comes from a multi-stand mill is due to the strip acquiring high levels of hot deformation as it passes through a hot tandem mill. However, there is insufficient time to allow any inter-pass recrystallisation. This results in suitably high levels of the desirable crystallographic cube texture when the material finally has time to recrystallise in the hot rolled coil.

The cold rolling reduction to achieve the required strength levels in the final gauge sheet also results in a nicely balanced crystallographic texture. This generates low earing after drawing the can.

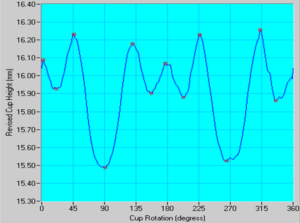

Figure 2 gives an example of an earing profile test result from world-class CBS produced via a hot tandem mill. It shows the desirable 6 ears at 45° and 0°/180° to the rolling direction.

Earing from a single stand hot reversing mill

Historically, there have been trials through existing hot reversing mills that simply replicate the ~3mm hot band gauge used in a hot tandem mill. These confirm that AA3104 CBS is not able to fully meet the strength and earing requirements specified by the can-makers.

Making CBS on a single stand hot reversing mill

Innoval Technology has considered three separate approaches to modifying the production schedule when using a single stand hot reversing mill to make CBS. These are outlined below. Each approach requires detailed experimental investigation to assess the effect on all of the product requirements.

- Change the alloy content of the aluminium outside that allowed within the AA3X04 (3004, 3104, 3204) alloys. This would mean that the property development during cold rolling is significantly modified. Clearly this approach would require the can-maker to agree to a compositional modification outside the accepted range of current CBS alloys. However, there can be commercial benefits of doing this especially for local markets.

- Take advantage of the detailed knowledge of how crystallographic texture develops in aluminium alloys by carrying out an anneal in the production route. This would de-activate the un-desirable PSN (Particle Stimulated Nucleation) recrystallisation sites that compete with the desirable cube texture sites.

- Carry out near-isothermal rolling in the last hot rolling passes on a coil-to-coil mill, as described in published patents. It is not easy to evaluate this on an industrial rolling mill. However, the Innoval Rolling Model can investigate the feasibility of controlling the rolling temperatures within the desired temperature range. This would be a precursor to more detailed hot deformation studies that can be carried out using existing laboratory simulation.

The risks

For each of these three options there are technical risks which we could easily explain. We can also offer an assessment of the likely commercial success, together with a detailed calculation of the Opex costs you might incur. In addition, we can evaluate the impact of rolling plant Capex investments specific to each solution.

In addition to these specific options for achieving the required balance of strength and earing in the final product, there are other Capex items that may be required at a plant that is not currently making CBS. These might include the correct molten metal filtration, and an electrostatic coating with post-lube on the final gauge product.

For an existing rolling plant, we’d usually make a site visit to evaluate other requirements. This is because it is important to assess the capability of existing hot and cold rolling equipment to control profile and gauge, since these affect other key attributes of the product.

I have worked on the metallurgy of beverage can materials for over 20 years. So, if anything in this blog has sparked your interest, please get in touch. You may also be interested in our Beverage Cans training course.