Posted on: 30th August 2019 by Dr. Michael Kenyon

As a technical consultancy, it’s critical that our aluminium knowledge is as up-to-date as it can be. Our clients rely on it!

One of the ways we make sure our aluminium knowledge is cutting-edge is by leading and participating in pre-competitive R&D projects. This blog describes some of the exciting and ground-breaking projects, funded by Innovate UK, that we are currently involved in.

What is Innovate UK?

Innovate UK is part of the UK Research and Innovation (UKRI) funding agency which invests in science and research in the UK. UKRI encompasses 7 Research Councils, Innovate UK and Research England working together with universities, research organisations, businesses, charities and government.

The objective of Innovate UK is to “drive productivity and economic growth by supporting businesses to develop and realise the potential of new ideas, including those from the UK’s world class research base”.

Only through Innovate UK funding are these projects made possible, thereby helping to improve the UK’s standing in global research. Often these collaborative projects result in new commercial partnerships, and strengthened existing partnerships, within UK industries and globally. Furthermore, the objective for many of these projects is to create new or develop existing UK supply chains with the potential for, importantly, significant investment into the UK’s manufacturing industry.

Sharing aluminium knowledge

Innovate UK funding enables the formation of highly skilled teams with the opportunity to gather and share information. In many cases, this even includes competitors collaborating who would not normally work together.

The collaborative R&D project teams, of which we are a part, consist of several organisations including OEMs and upstream manufacturers. We currently work as a consortium member on several active projects which you can read about below.

All current projects are based around the utilisation of recycled aluminium and its increased implementation in the automotive industry. The overall aim is to produce lighter weight vehicles, with a focus on electric and hybrid vehicles.

Active Innovate UK projects

REALITY: REcycled Aluminium through Innovative TechnologY

The concept for this project is to develop industrial sensor-based scrap sorting technologies. Furthermore, it incorporates the remelting and full-scale coil production of recycled aluminium. Firstly, the new technology will have the ability to sort wrought from cast aluminium. Secondly, it will have the ability to sort wrought alloys into the different alloy types. Subsequently, the project will produce and characterise recycled scrap-based sheet.

The partners in this project are Jaguar Land Rover, Axion Recycling Ltd, Novelis, Norton Aluminium, Brunel University, the University of Warwick and Innoval.

AL-ULEV: ALuminium for Ultra Low Emission Vehicles

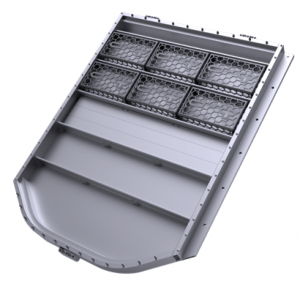

This project is to develop a disruptive alloy and extrusion design for battery enclosures. The battery enclosures will be for a new generation of lightweight hybrid and electric vehicles for the UK market. Furthermore, the project will include part integration into the Jaguar I-PACE, figure 1.

The partners are Constellium (Lead Partner), Brunel / BCAST, Gordon Murray Design and Innoval.

RACEForm: Rapid Aluminium Cost Effective Forming

This project aims to create a UK supply chain that can deliver lightweight aluminium automotive structural components formed by the Hot Form Quench process (HFQ®) in high volume. This is to meet clear demand from automotive OEMs seeking to lightweight their existing & future vehicle fleets. Most importantly, the OEMs will be able to offer lower CO2 emissions & fuel savings to their customers.

The partners in this project include Impression Technologies, Gestamp, Novelis, Imperial college London, Brunel University and Innoval.

Starting soon

LIBERATE: Lightweight Innovative Battery Enclosures using Recycled Aluminium TEchnologies

This project aims to design and develop recyclable aluminium-intensive components for a vehicle battery enclosure. It is due to start at the end of 2019.

The partners are Constellium, Impression Technologies, BMW, Volvo, Granger and Worrall, Brunel University, Warwick Manufacturing Group and Innoval.

To serve our clients in the best way possible, it’s important that we know about the latest, cutting-edge developments in aluminium. To this end, we’re involved in many collaborative R&D projects funded by the UK Government’s Innovate UK. Many of these projects focus on vehicle lightweighting, such as RACEForm (Rapid Aluminium Cost Effective Forming).

The objective of the RACEForm project is to validate Hot Form Quench (HFQ®) technology for mass production.