Background

Businesses that capture and share knowledge at all levels are able to find new ways to improve quality, standardise operations to reduce costs and identify and replicate best practice across different parts of the company. That was certainly the experience at Morgan Carbon of Morriston in Swansea; manufacturers of electro-graphitic carbon blocks used mainly in the automotive, rail and domestic appliance sectors.

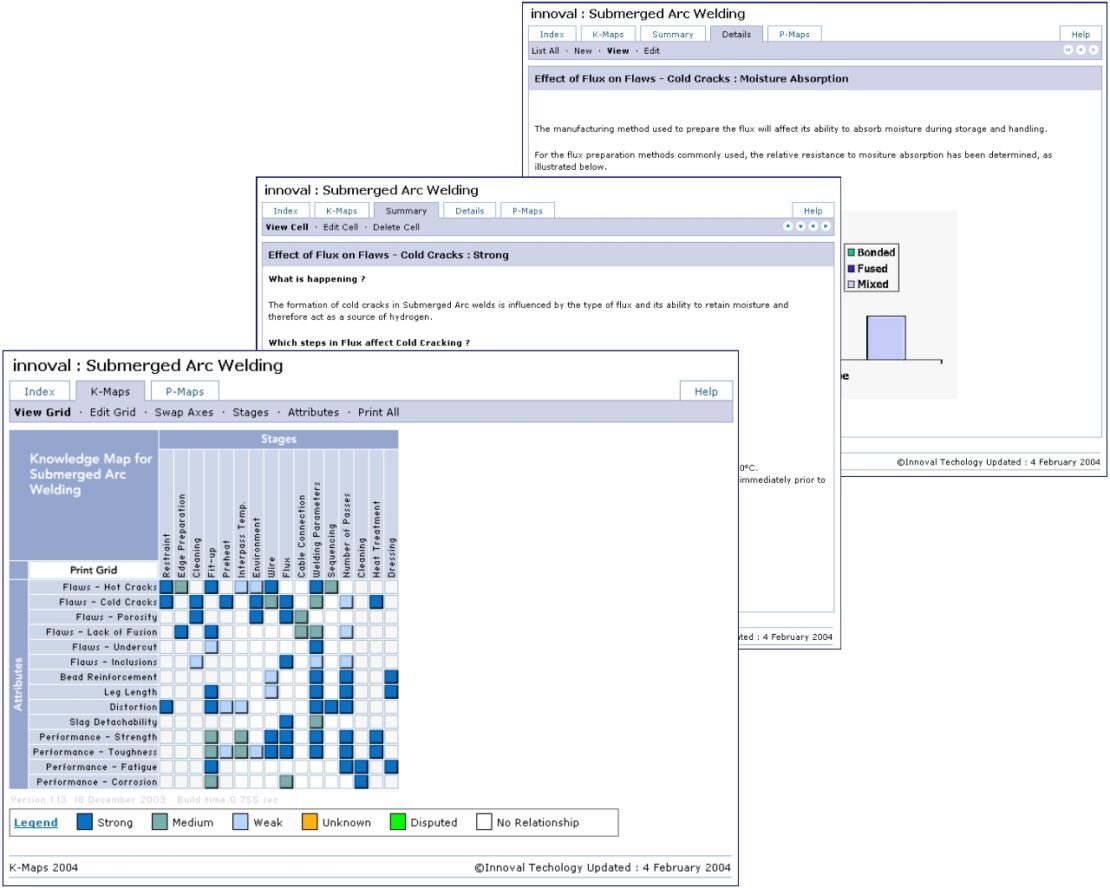

Morgan Carbon invested in our K-Map software, which provides an easy to use, structured way of capturing all of the knowledge contained within a plant. Developed specifically for manufacturing companies, K-Maps are a practical knowledge mapping tool suitable for capturing information and data about every process and product.

How we were involved

Gary Mahon and Helen Forrest worked with employees at Morgan Carbon to map all of the relevant knowledge about their products and processes onto a matrix within the K-Map software that shows visually how each process stage affects the product attributes.

The “interactions” between the product attributes and each process stage were defined during a detailed workshop, where tacit knowledge (i.e. what individual team members knew) about the nature of each interaction and the quality controls in place was identified and captured.

Further data to support the tacit knowledge was then acquired and stored within the software package.

Services Involved

- K-Maps

- P-Maps

This case study appears as an article in the 2004 edition of ‘innform’; the newsletter of Innoval Technology.

The K-Map is an excellent tool for pulling out information. We have captured knowledge from people who will not be available to us in 10 years’ time. The few days spent mapping the knowledge was definitely time well spent.

Dr Chris Spacie, Technical Director

The K-Map format is very useful for quickly and easily storing and retrieving practical knowledge. So far we have mainly used it as a process problem-solving tool, but it has definite potential to do a lot more, particularly within training. It can give people knowledge of the parts of the production system they are not so familiar with, enabling them to contribute to the business quicker than if they had to wade through reports and manuals.

Dr Albert Easton provides technical support to the production line at Morgan Carbon. He was involved in the knowledge mapping exercise.