Posted on: 5th September 2016 by Dr. Gary Mahon

Extruders recognise that billet quality is an important aspect of extrusion plant performance. However, it’s not always easy to prioritise where valuable resources should be focussed when trying to improve the efficiency of an extrusion plant.

By using knowledge mapping it is possible to clearly understand the impact of billet quality on extrusion plant performance. Then we can focus on evaluating the key aspects of billet quality that can impact plant output and efficiency. I’ll explain the methodology in this blog.

Knowledge Mapping

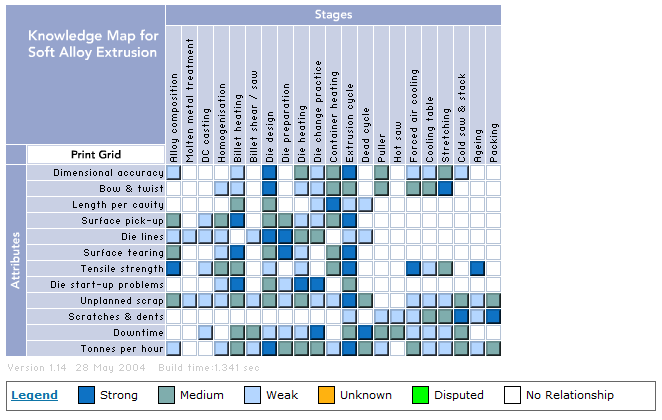

Innoval Technology uses a powerful, yet simple, approach. A matrix identifies the process stages which affect the characteristics (or attributes) of the extrusion operation; Figure 1. This is known as a Knowledge Map (or K-Map). It is built by breaking down the process of extruding into discrete stages on the axis across the top. The other axis lists the important attributes of operating an extrusion plant. These attributes cover the quality of the product as required by the customer, such as dimensions, surface and mechanical properties. They also cover factors which impact the economics of the overall plant operation.

For demonstration purposes I’ve kept this list short, but we can add many more attributes if needed. We could also expand the process stages to cover a greater number. However, I’ve kept this example simple in order to focus on the four stages on the left of the list which make up billet supply. These are Alloy composition, Molten metal treatment, DC casting and Homogenisation. This particular K-Map is a generic map appropriate to a gas fired log furnace followed by a hot billet shear or saw. The shear/saw feeds a direct extrusion press producing soft alloy profiles.

Top level K-Map

The K-Map shows where each of the process stages effects the attributes of the extrusion operation. A coloured square indicates where there is an interaction. Colour coding ranks the relative importance of each process stage on each of the attributes. The matrix highlights strong, medium and weak interactions, as indicated in the legend. The K-Map also captures any disputed or unknown relationships, but these are not required in this example.

It is important to realise that, if we look across the rows of the matrix, we can compare the strengths of the relationships. This allows us to assess the relative importance of each process stage on that particular attribute.

As you can see, the top level matrix alone is a powerful tool to carry out a structured and repeatable assessment of an extrusion plant.

However, the real strength lies in knowing why a particular process stage affects an attribute. We can use this sort of transferable knowledge during a technical audit of an extrusion plant. It can help to identify the specific areas of focus for process improvement activities. The second level of the K-Map software, which sits behind each coloured square, captures and stores this ‘why’ information.

In the rest of this post I will concentrate on those billet-related issues that are at least as important as some of the process stages (which are within the control of the extruder).

Stages of Billet Manufacture

There are actually many separate steps which make up the four stages of billet manufacture in our K-Map. However, I’ve grouped them together for simplicity in this example. For a more detailed knowledge-map of extrusion billet, we would break down the stages into steps as follows;

- Alloy composition – Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, trace elements.

- Molten metal treatment – degassing, filtration, grain refinement.

- DC casting – launder materials, casting technology, casting conditions.

- Homogenisation – batch or continuous, heating rate, peak metal temperature, time at temperature, cooling rate.

Billet quality: composition on strength

The K-Map (Figure 1) shows that alloy composition has a relatively important effect on several attributes. The strong effect of composition on tensile strength is no surprise. This is the reason why many 6000-series alloy variants exist with their differing levels of Mg and Si. These elements provide strengthening via the volume fraction of fine Mg2Si particles which form during age hardening.

One of the key aspects is to achieve consistency of strength which, in part, is about controlling the range of alloying additions made. Although the composition of an alloy can fall within the 6060 composition, the T5 temper UTS can be in the range 150 to 270 MPa. This would clearly be unacceptable for many end-use applications. The effect of Cu, Mn, Cr and other trace elements on strength also emphasises the need for tighter composition tolerances than those shown in the ISO specifications. Typically this needs to be ±0.02 wt.% for the major alloying elements.

Billet quality: composition on surface pick-up

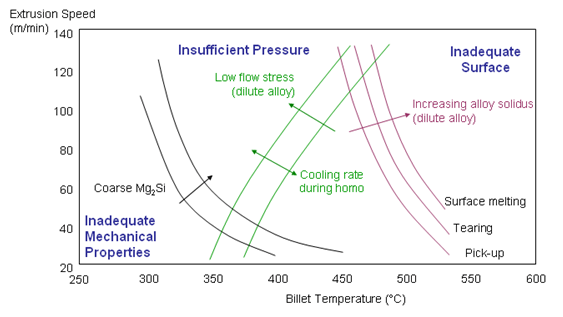

The other more important influences of alloy composition are the effects on the surface attributes of the extrusion. In this case, we’re talking about surface pick-up and surface tearing. The extrusion limit diagram in Figure 3 demonstrates these influences.

At high billet temperatures and extrusion speeds the surface starts to deteriorate. This is initially because of pick-up, and then via tearing, and eventually surface melting. Moving to a more dilute alloy shifts the limiting conditions to higher speeds, thus increasing tonnes per hour (subject to the other factors indicated in the K-Map).

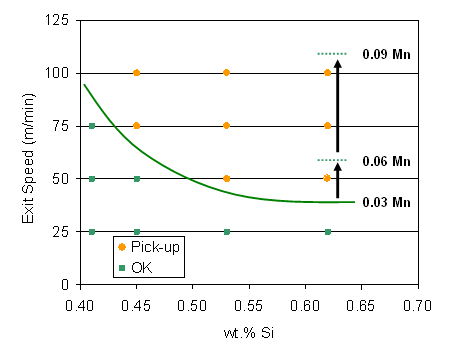

However, there is also an important mechanism caused by the intermetallic particles in the billet which form the β-phase during DC casting. The β-phase can transform to the α-phase during homogenisation. Some of the influences of alloy composition on pick-up are shown in Figure 4. It shows how increasing the Si content of the alloy gives pick-up at lower extrusion speeds. This is as a consequence of Si encouraging the formation of the Si-rich β-phase.

Figure 4 also shows the effect of increasing Mn on reducing pick-up, even at the highest extrusion speeds. This happens because Mn is an α-phase stabiliser. Typically, it is desirable that at least 70% of the intermetallics are the α-phase. However, as the K-Map shows, there are many other influences on the surface attributes and there is no cut-off below which quality necessarily deteriorates.

Billet quality: homogenisation on surface pick-up

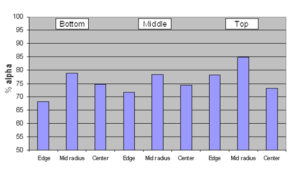

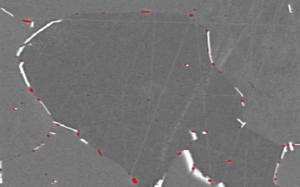

The other important influence of billet quality comes via the homogenisation stage. This is a consequence of both the β to α transformation, and the dissolution and precipitation of the Mg2Si phase. The time and temperature of billet homogenisation controls the extent to which the β-phase transforms to α intermetallics. This in turn affects surface pick-up and surface tearing, as described previously. It is important to measure the consistency of this transformation.

It is possible to have significant variation across the billet section and along the length, as shown in Figure 5.

Furnace control gives rise to this variability. Furthermore, it can vary significantly between pusher and batch furnaces.

Billet quality: homogenisation on strength

Another important influence is on tensile strength. The homogenisation conditions will influence both the extent of dissolution of the as-cast Mg2Si and the re-precipitation of a much finer distribution of Mg2Si during controlled cooling to room temperature. If the billet cools too slowly, the Mg2Si is too coarse to re-dissolve during the extrusion cycle. Consequently, the Mg and Si are not available to take part in the subsequent age hardening stage.

An SEM image can show the Mg2Si distribution in the as-homogenised billet (Figure 6) which allows us to easily quantify the particle size distribution.

There are other lesser effects caused by both the alloy composition and homogenisation. These are principally a consequence of the effect on flow stress and its associated influence on metal flow through the die during the extrusion cycle. However, as you can see in the K-Map, the effects are only weak in comparison to the other more significant stages within the extrusion plant.

As mentioned above, we’d capture the ‘why’ information (as described in the previous four sections) in the Level 2 pages of the K-Map.

Supplier fingerprinting

An extrusion plant K-Map highlights the more critical process stages that are within the control of the extruder and their influence on the quality and economic performance of the plant.

Billet quality is also an important input that frequently is outside the control of the extruder. Consequently, assessment of billet quality by the extruder is an important control. However, extruders and billet suppliers need to work in partnership to ensure they have systems in place to ensure quality consistently meets extruders’ needs. Independent audits and experimental evaluations are a critical part of that relationship. We offer these services at Innoval Technology.

To run an efficient plant extruders should not just rely on the lowest cost suppliers. For the billet suppliers, evidence of high billet quality is a great product differentiator, especially in challenging market conditions. At Innoval we’re able to carry out independent characterisation of billet quality which we term ‘supplier fingerprinting‘. We can also provide training and mentoring of extrusion personnel.

Finally, if you want to make your whole process, from billet storage through to packing, more efficient we can help. Using proven methodology, we will work with your team to analyse what you do and remove the wasteful activities. For more information about how we help aluminium extrusion companies, click here.