Posted on: 19th February 2024 by Dr. Junjie Wang

Every aluminium rolling company and extrusion company pays attention to the surface properties of their products. Surface properties are usually different to those of the underlying bulk. In most cases, aluminium producers and end users need to regularly check surface quality, especially for surface engineered products, so it’s important to understand surface chemistry.

In this Insight, I will introduce some widely used techniques for analysing the surface chemistry of aluminium products. I will focus on their use with examples, whilst keeping the fundamental principles to a minimum.

Infrared Spectroscopy (IR).

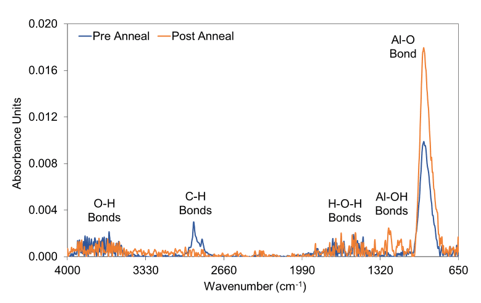

IR can analyse chemical substances or functional groups on bare aluminium surfaces, or coatings on aluminium. There are good examples in one of our previous Insights about Understanding your aluminium oxide surface. Based on extensive experience, our surface experts have developed a UKAS-accredited method for measuring the oxide film thickness on aluminium surfaces. We use this relatively simple and fast method to help our customers control and optimise their processes. These processes include annealing and brazing, etc.

In all cases of painting, lacquer coating and adhesive bonding of aluminium surfaces, both oxide and hydroxide groups on the aluminium surface play critical roles. Fourier transform infrared (FTIR) spectroscopy is a sensitive technique which can distinguish between aluminium oxide and hydroxide groups. Most other techniques are not capable of doing this.

If you have an IR microscope with a scanning function, as we do at Innoval, you can map many chemical species on your aluminium surface. This can show the coverage of your functional coating on the aluminium surface, or it can give the distribution of unwanted contamination. Figure 1 shows some examples of FTIR spectra.

Glow Discharge Optical Emission Spectroscopy (GDOES).

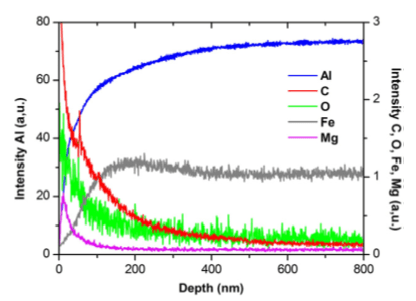

GDOES produces elemental depth profiles by sputtering surface atoms from an aluminium sample using a plasma. This is very useful to show how the composition varies with depth on coated aluminium surfaces (Figure 2). It can be used for many types of coating include paint, lacquer, anodic films and most chemical conversion coatings. Examining the surface chemistry of bare aluminium is also useful if there have been changes to the chemical composition at the surface or within the near-surface region. GDOES can measure all elements simultaneously, including light elements such as H, Li, C, etc.

X-ray Fluorescence Spectroscopy (XRF).

XRF is a non-contact, non-destructive technique that can measure the chemical composition and film thickness/coat weight of aluminium samples. Many automotive and aerospace OEMs require suppliers to provide the coating weight of the conversion coating film on aluminium parts. This is for quality control purposes. For example, for Ti/Zr passivation films on aluminium automotive sheet, a typical range of coat weight is 1 – 8 mg/m2 for Ti and Zr respectively. XRF is the technique of choice for this. Furthermore, in the scrap metal recycling industry, facilities employ XRF for fast and accurate sorting of non-ferrous scrap after the aluminium fraction has been removed.

X-ray Photoelectron Spectroscopy (XPS).

XPS is an ultra-high vacuum technique. It is highly sensitive to chemical composition and bonding states in the outermost 2 – 10 nm of the aluminium surface. We can also use XPS for elemental depth profiling. Suppliers and manufacturers use XPS to measure the applied weight of the A951 conversion coating increasingly used for aluminium intensive vehicles in North America like the best-selling Ford F150 truck.

Energy Dispersed X-ray Spectroscopy (EDX).

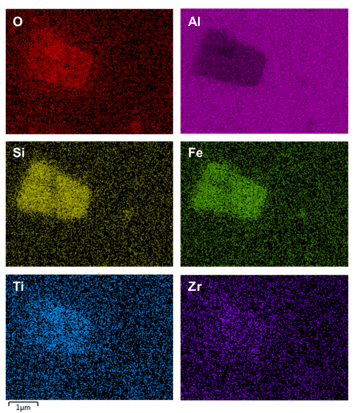

Most electron microscopes have an EDX facility that can provide compositional analysis at any site on the aluminium surface where there are interesting features. Such feature analysis is extremely useful for failure investigations and product quality issue diagnosis.

Using EDX attached to a scanning electron microscopy (SEM), it is possible to obtain elemental distribution maps at a scale between a few microns to about 1 mm (Figure 3). You can also get qualitative elemental information of a surface feature as small as 100 nm in size. As I described in a previous Insight, surface characterisation at low accelerating voltage such as 1.5 kV helps reveal fine details of the outermost aluminium surface layers. However, EDX requires a certain accelerating voltage to gain meaningful elemental signals from the aluminium surface, as well as a highly-skilled, experienced operator.

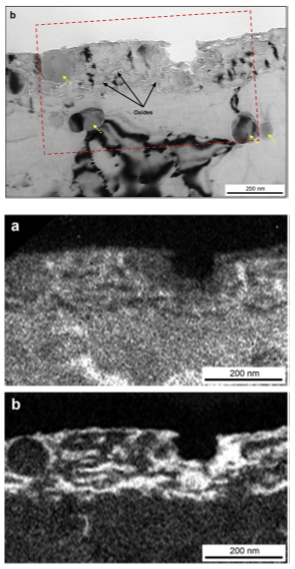

EDX attached to a transmission electron microscope (TEM) provides meaningful EDX elemental point analysis from features even below 10 nm size. However, this depends on the capability of the TEM and the EDX system. EDX on many analytical TEMs can provide elemental maps or line scans to reveal the distribution of elements in the examined region.

Electron Energy Loss Spectroscopy (EELS).

Users typically attach an EELS facility to a TEM or a scanning TEM (STEM). This can provide chemical compositional information down to the atomic scale, with higher resolution than that of EDX, which makes it very useful to analyse nano-scale thin films on aluminium surfaces. Figure 4 shows an example.

Other ways to analyse surface chemistry.

There are other techniques capable of analysing the surface chemistry of aluminium products. These include Raman spectroscopy, glow discharge mass spectroscopy (GDMS), time of flight secondary ion mass spectroscopy (ToF-SIMS), etc. These are more specialised, but we are hoping to cover them in a future Insights article for those who are interested.

In summary, it is very important to choose appropriate techniques for surface chemistry analysis based on the overall purpose of the examination and the quality of the supplied samples. Innoval’s extensive experience in this area means that we can help you choose the most appropriate techniques from our world class in-house and partner network facilities. Most importantly, we will relate our analysis of the surface chemistry of your aluminium products to the relevant real-world, industrial quality standards and resultant performance in service. Please contact us for further information.

Finally, if you’d like to learn more about aluminium surfaces, why not sign up to our Introduction to Aluminium Surfaces & Treatments online training course? You can find the dates of the next course in our Public Courses Schedule.

The main image on this post shows the surface of an i-Phone 14 case. It was viewed under optical microscope by Dr Zelong Jin.