Posted on: 10th June 2016 by Kyle Smith

Over the years we have provided technical support to potential investors in several new rolling operations. These investors recognised that, by not involving technical expertise, they were at risk of not achieving the intended financial returns from their aluminium rolling plant.

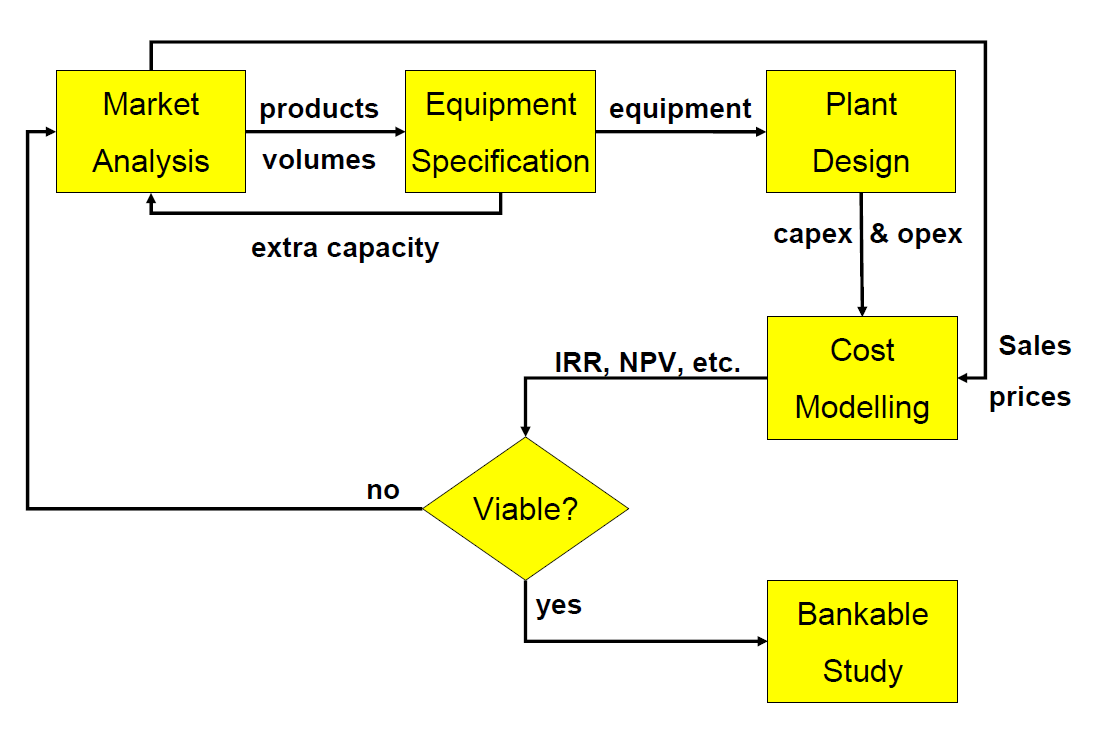

At Innoval we have a very methodical approach to aluminium rolling plant design, as you can see by the flow diagram in figure 1. In this post I will explain a little about what’s involved in the early stages of this process.

A Methodical Approach

Figure 1 highlights the need to optimise products and volumes in order to make best use of the chosen equipment and to increase the viability of the plant. This must be done with a good technical knowledge of product quality specifications, product margins and equipment capabilities.

When the product mix is defined, the plant equipment can be specified and the capital expenditure (CAPEX) and operational expenditure (OPEX) data calculated for use in a process cost model. The cost model is then used to evaluate financial performance and viability of the investment using metrics such as Internal Rate of Return (IRR) and Net Present Value (NPV) calculations.

If financial viability is not achieved then a significant change to the product mix and equipment may be required to achieve the desired financial return on investment.

Once a viable configuration has been achieved then the project can move forward to more detailed studies and then on to construction and operation.

Market Analysis

The first step in designing a new aluminium rolling plant is a thorough analysis of the potential home and export markets for the plant’s products. As a technical partner, we can add a useful end-user perspective to compliment this analysis by verifying any assumptions and ensuring logical conclusions are obtained.

Data on product sale prices must be gathered for use later in cost modelling. Some products cost more to produce and so a high sale price does not necessarily result in a high profit for the business.

The analysis must include an assessment of the competitors active within the same markets, either locally or abroad. Decisions to compete locally or within export markets can have an impact on the product quality standards required. This can influence the choice of equipment in the plant.

The final outcome of this analysis will be the proposed product mix for the plant.

Assessing the Technical Challenges

The exact product requirements will determine the choice of equipment and technology required in the aluminium rolling plant. For example, a state-of-the-art Hot Reversing Mill (HRM) followed by a 3 or 4 stand Hot Tandem Mill (HTM) is capable of rolling all products to world class quality requirements and has the largest capacity of all options. A coil-to-coil Hot Reversing Mill has a lower capacity and may result in different quality attributes for some products.

Traditional continuous casting technologies, such as belt or twin roll casting, have lower capacities and present further limitations on the range of world-class products that can be produced. However, some of these limitations are now being challenged by new process technologies such as the Arconic Micromill.

Consideration should also be given to ‘future-proofing’ the equipment to meet evolving customer needs, such as tightening of product specifications and increasing coil widths and lengths.

Equipment Specification for an Aluminium Rolling Plant

Clearly it is important to get the number of machines and the size of each machine correct. This requires careful capacity calculations and the results are often dependent on the mix of products being processed. Because some equipment is only available in certain sizes, there can be spare capacity available. It is important to assess this as an opportunity to process and sell more product volume if the market can sustain it.

It is crucial to have a good understanding of the magnitude of process losses at every stage of the operation (recoveries) and how these will evolve and improve during the ramp up of a new aluminium rolling plant. This knowledge will determine the product volumes which need to be processed to meet the customer requirements.

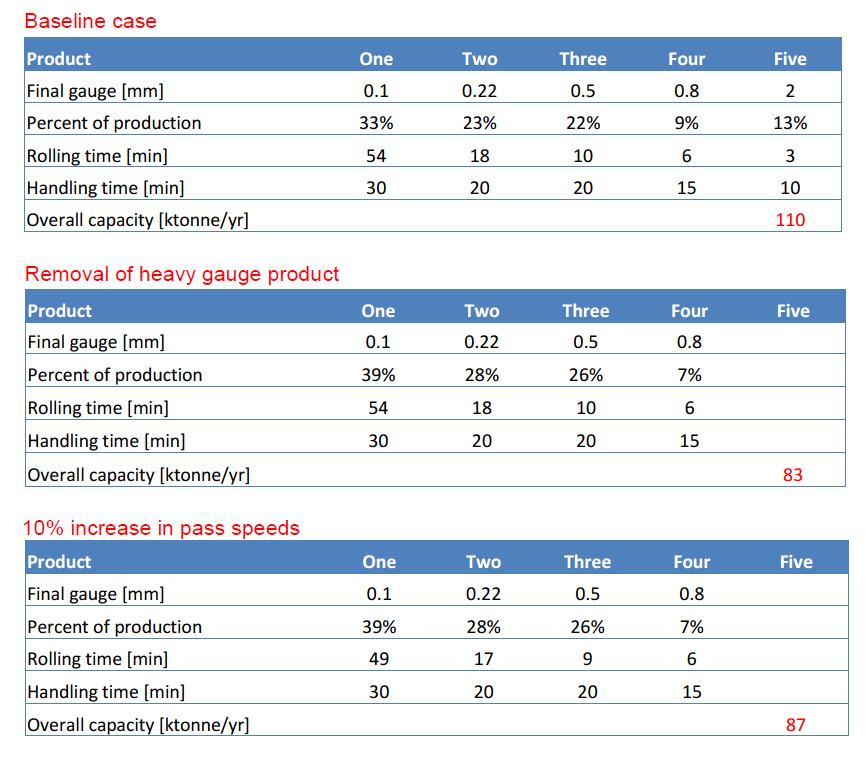

A rolling mill represents a significant fraction of the total investment Capex so it must be specified very carefully. Figure 3 shows the overall capacity of a rolling mill for three different cases. From this example it is clear that the capacity of the rolling mill depends on the product mix, particularly the final gauges. The capacity also depends on rolling speeds, but the relationship is not 1-to-1 because of the handling time between rolling passes.

To calculate the correct inputs for a rolling mill capacity model, we have developed complex physically-based models that can take account of the capabilities of the mill and the metallurgical and surface requirements of the products.

This blog post was originally written by Dr Tom Farley who has now left the company. Please contact Kyle Smith if you have any questions.