Posted on: 19th May 2016 by Private: Helen Forrest

Last week saw the first of two Aluminium Rolling Technology Courses to take place in Banbury this year. The course covered all the key aspects of hot and cold rolling of aluminium flat products. One of the lectures at the start of the week was Process Metallurgy which I got the chance to attend.

Like many of you, I work within the aluminium industry but I’m not a metallurgist by training. Although I have an appreciation of the alloy and temper designations for aluminium, it’s not something I use on a daily basis. My knowledge is therefore very basic. However, thanks to Vicente Martin who delivered the lecture, my knowledge of alloy and temper designations, and of aluminium metallurgy in general, has now greatly increased.

I think it’s useful sometimes to go ‘back to basics’, so I would like to share with you the parts of our Process Metallurgy lecture that cover the alloy and temper designations. I hope you find them useful.

Alloy Designations for Wrought Aluminium

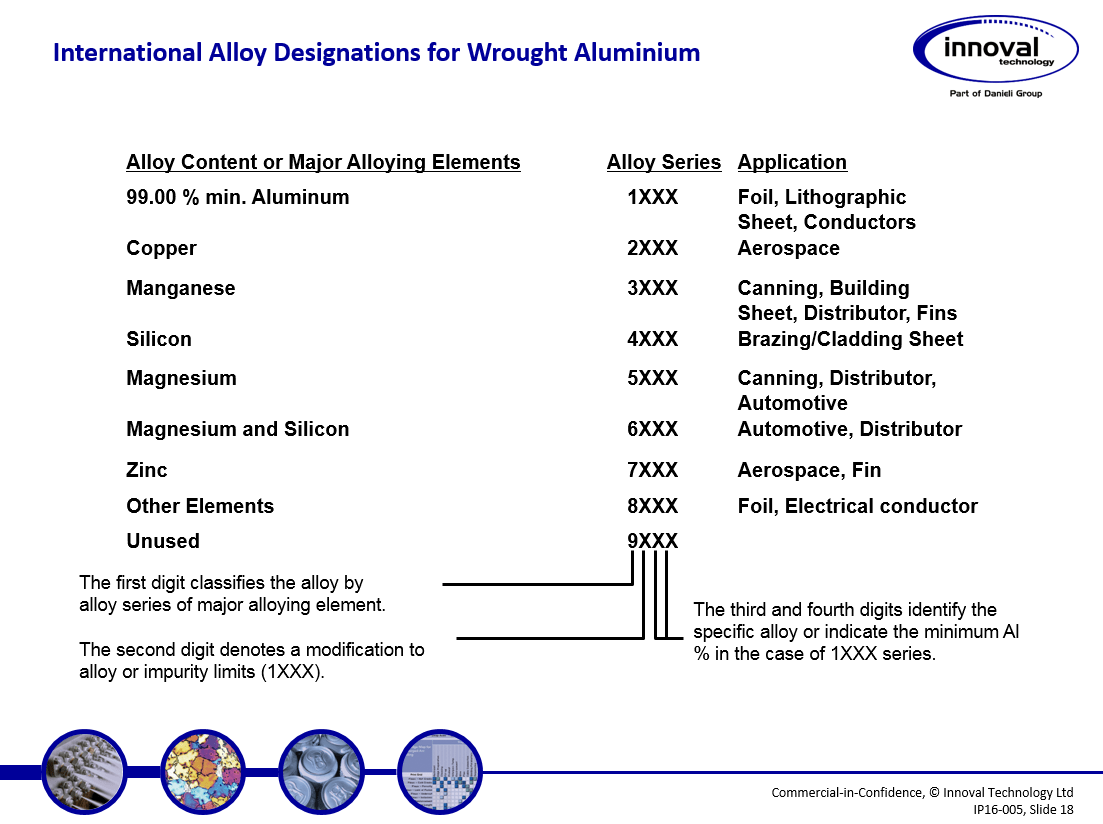

All commercially available wrought aluminium products are assigned a specific alloy designation number using the International Alloy Designations. These originally came from the Aluminum Association in North America, but they are now accepted as the international standard.

The alloy numbers are divided into a specific alloy series based on either the aluminium content, as in the case of the 1000 series alloys, or on the major alloying element(s) present. For each alloy number, the designations define a specific compositional range. These ranges are much wider than the compositional specification from product suppliers.

For more information about the compositional ranges, you might want to have a look at the Aluminum Associations’s Teal Sheets (International Alloy Designations and Chemical Composition Limits for Wrought Aluminum and Wrought Aluminum Alloys).

The applications shown in Figure 1 are given as a rough guide and are not meant to limit the uses of specific alloys.

Please be aware that a different set of designations and chemical composition limits exist for aluminium alloys in the form of castings and ingot.

Temper Designation System

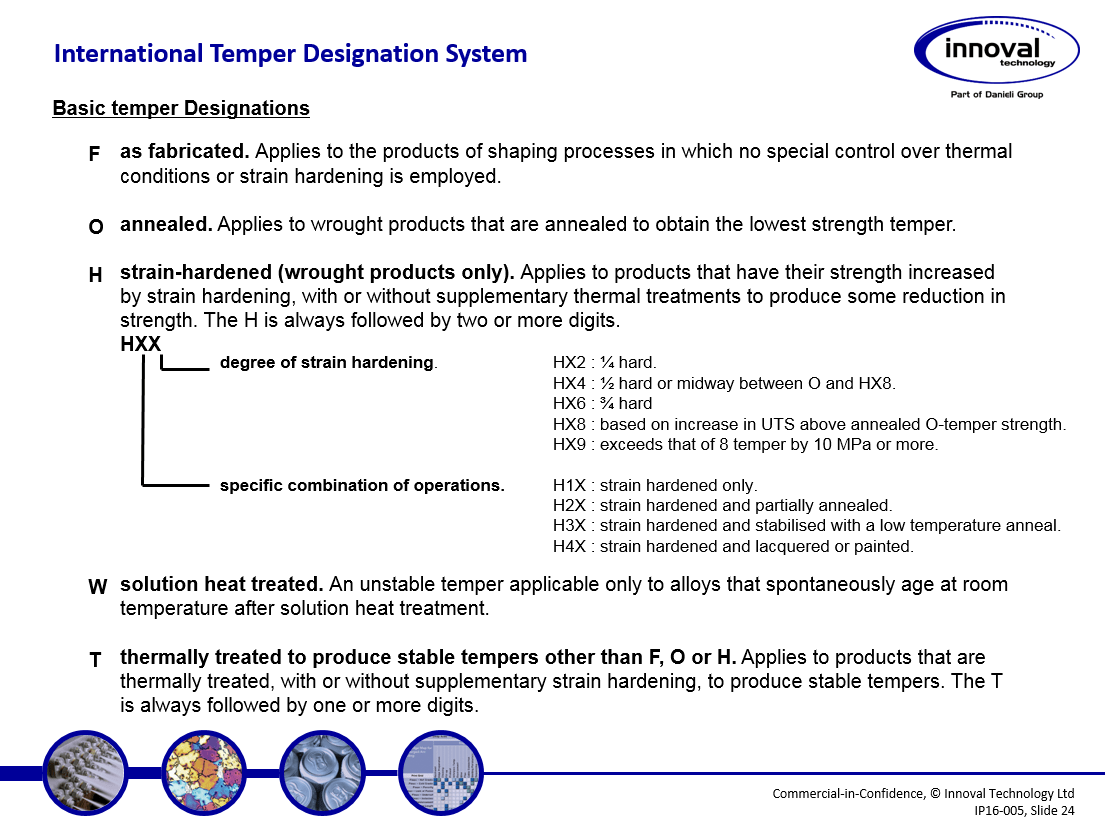

This lettering and number system describes the thermo-mechanical treatment which has been applied to a particular alloy to achieve its mechanical properties. This designation follows the alloy designation; for example 5182-H18 refers to the alloy 5182 which has been strain hardened to increase the UTS by 90MPa.

The tempers shown in Figure 2. are those relevant to the non-age hardened products.

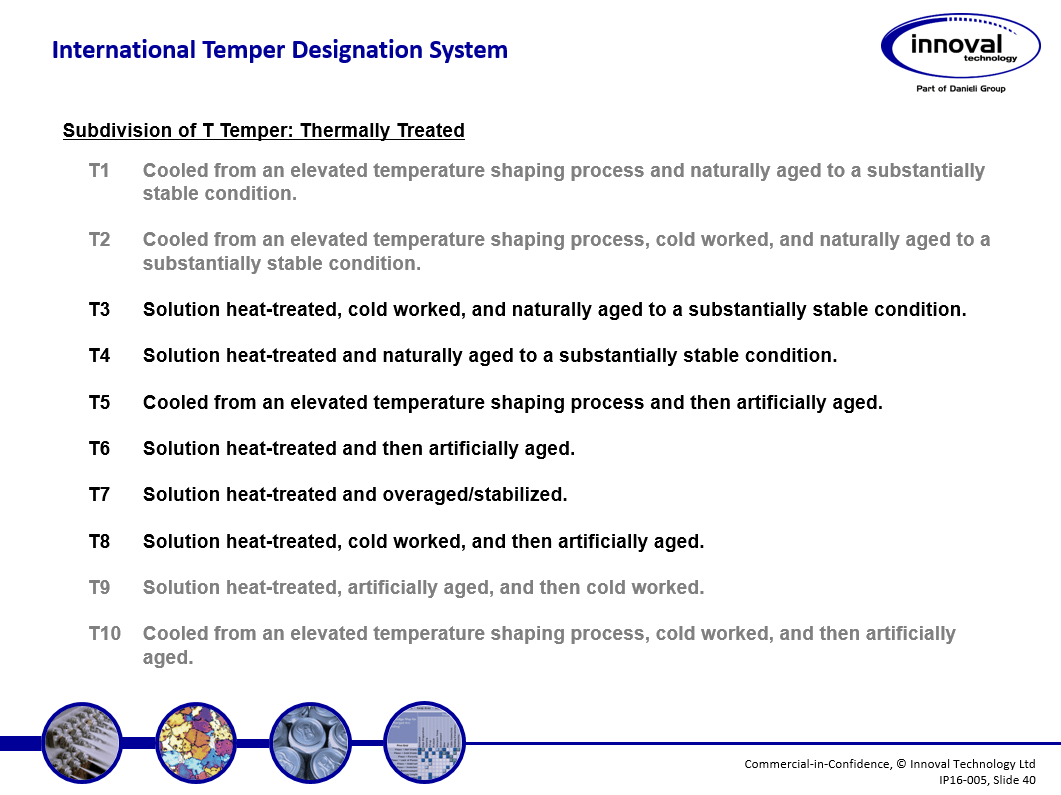

Age hardened products are usually in the T-temper, for which there are many additional digits to describe the thermo-mechanical treatments applied following a solution heat treatment (W temper). These are shown in Figure 3.

There’s more detailed information about temper designations from the Aluminum Association in Aluminum Standards and Data 2013 (Metric).

If you’ve found his useful you might want to take a look at our Introduction to Aluminium training course. This course is the perfect starting point for anyone entering the aluminium industry. You learn about the production and processing of aluminium, its properties and more about how alloy and temper designations work. We also cover metallurgy, surface treatment and experimental techniques for problem solving.